Gaskets in oil and gas industries ( Types, buy, sale, price, export, import, from to in uae dubai )

Gaskets play a crucial role in the oil and gas industry by providing a seal between two surfaces to prevent leakage of fluids or gases. They are essential components in pipelines, valves, pumps, and other equipment used in the extraction, production, transportation, and refining of oil and gas.

There are several types of gaskets used in the oil and gas industry, including spiral wound gaskets, ring joint gaskets, and metal gaskets. Each type of gasket has its own specific characteristics and is suited for different applications based on factors such as temperature, pressure, and chemical compatibility.

In the oil and gas industry, gaskets are bought and sold by companies that specialize in the manufacturing and distribution of industrial seals and gaskets. These companies provide a wide range of gaskets to meet the diverse needs of the industry, from standard sizes to custom-made gaskets for specific applications.

The price of gaskets in the oil and gas industry can vary depending on the type of gasket, the material it is made from, and the quality of construction. Companies often negotiate bulk pricing with gasket suppliers to reduce costs and ensure a steady supply of gaskets for their operations.

The UAE, particularly Dubai, is a hub for the oil and gas industry in the Middle East region, making it an important market for gasket manufacturers and suppliers. Many companies in the UAE rely on imported gaskets from countries like the US, Germany, and China to meet their needs for high-quality seals and gaskets.

Exporting gaskets from countries like the US to the UAE can be a lucrative business opportunity for gasket manufacturers looking to expand their market reach. Similarly, importing gaskets from other countries to the UAE can help local companies access a wider range of gasket options to meet their specific requirements.

In conclusion, gaskets are an essential component of the oil and gas industry, providing a reliable seal to prevent leaks and ensure the safe and efficient operation of equipment. Companies in the UAE can benefit from the diverse range of gaskets available on the market, both domestically and internationally, to meet their operational needs and maintain the highest standards of safety and performance.

n the oil and gas industries, gaskets play a crucial role in ensuring the safe and efficient operation of equipment and pipelines. These industries operate in harsh and demanding environments, with high pressures, temperatures, and corrosive materials present. Gaskets are used to create a seal between two mating surfaces to prevent leaks and ensure the integrity of the system.

There are several types of gaskets used in the oil and gas industries, each with its own unique characteristics and applications. Some of the most common types of gaskets used in these industries include:

1. Spiral-Wound Gaskets: Spiral-wound gaskets are made by winding a metal strip and filler material in a spiral pattern. These gaskets are suitable for high-pressure and high-temperature applications and provide excellent resilience and sealing performance.

2. Ring Joint Gaskets: Ring joint gaskets are made from metal and are used in applications where high pressure and temperature are present. These gaskets are designed to withstand extreme conditions and provide a reliable seal.

3. Non-Metallic Gaskets: Non-metallic gaskets are made from materials such as rubber, silicone, or PTFE. These gaskets are used in applications where chemical resistance and flexibility are required. Non-metallic gaskets are also suitable for low-pressure and low-temperature applications.

4. Camprofile Gaskets: Camprofile gaskets are made from a metallic core with a non-metallic filler material. These gaskets provide excellent sealing performance and are suitable for high-pressure and temperature applications.

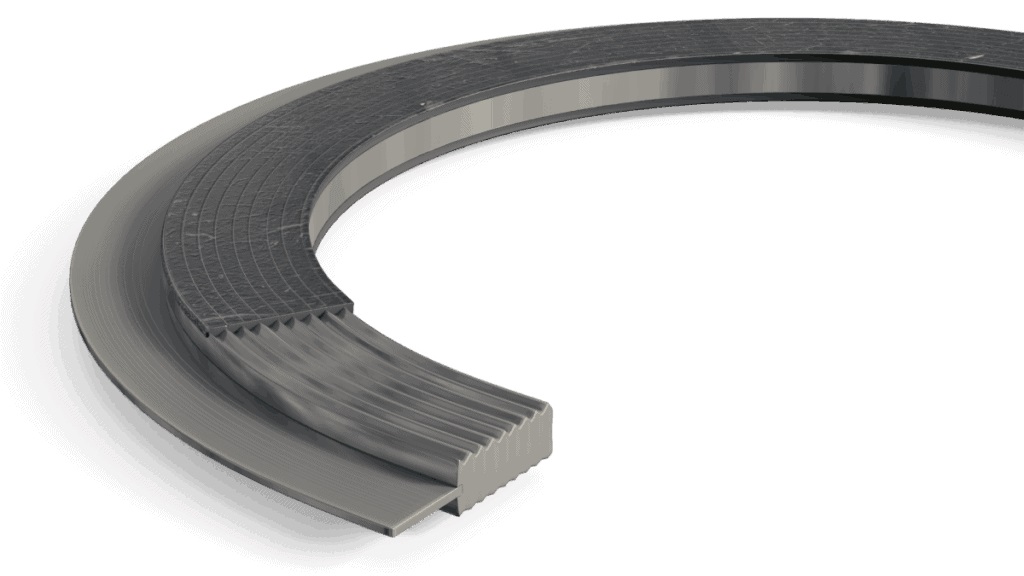

5. Kammprofile Gaskets: Kammprofile gaskets are made from a metallic core with serrated faces and a flexible covering material. These gaskets are designed to provide a tight seal and are suitable for high-temperature and high-pressure applications.

6. Elastomer Gaskets: Elastomer gaskets are made from materials such as rubber or silicone and are used in applications where flexibility and chemical resistance are required. These gaskets are suitable for low-pressure and low-temperature applications.

In conclusion, gaskets play a critical role in the oil and gas industries by ensuring the safe and efficient operation of equipment and pipelines. There are several types of gaskets available, each with its own unique characteristics and applications. It is essential to select the right type of gasket for each specific application to ensure a reliable seal and prevent leaks. By using high-quality gaskets, the oil and gas industries can maintain the integrity of their systems and prevent costly downtime and environmental damage.

Gaskets Brands in oil and gas industries

Gaskets are an essential component in the oil and gas industries, used to create a seal between two mating surfaces to prevent leakage of fluids or gases. They are commonly used in pipelines, valves, pumps, and other industrial equipment to ensure a reliable and efficient operation.

There are several reputable gasket brands that are widely used in the oil and gas industries, known for their high quality and durability. These brands invest in research and development to develop innovative gasket materials that can withstand high temperatures, pressures, and aggressive chemical environments commonly found in oil and gas applications.

One such brand is Garlock, a leading manufacturer of gaskets and sealing solutions for the oil and gas industry. Garlock gaskets are known for their superior performance and reliability in demanding applications. They offer a wide range of gasket materials, including compressed fiber, rubber, and PTFE, to suit various operating conditions.

Another well-known gasket brand in the oil and gas industry is Flexitallic, which specializes in metal gaskets designed for high-pressure and high-temperature applications. Flexitallic gaskets are used in critical joints where safety and reliability are paramount, such as in oil refineries, petrochemical plants, and offshore drilling platforms.

Spiral Wound Gaskets are also popular in the oil and gas industry, known for their excellent sealing performance and ability to handle extreme operating conditions. These gaskets consist of a metal winding strip and filler material, providing a strong seal that can withstand high pressures and temperatures.

In addition to these brands, there are several other gasket manufacturers that cater to the specific needs of the oil and gas industry. These brands offer a wide range of gasket materials, sizes, and configurations to meet the diverse requirements of oil and gas applications.

When selecting a gasket brand for use in the oil and gas industry, it is essential to consider factors such as operating conditions, pressure, temperature, and chemical compatibility. It is also important to choose a reputable brand with a proven track record of providing high-quality gaskets that meet industry standards and regulations.

In conclusion, gaskets play a crucial role in ensuring the safe and efficient operation of equipment in the oil and gas industries. By choosing a reliable gasket brand that offers high-quality products designed for demanding applications, companies can minimize the risk of leaks, downtime, and costly maintenance issues. Ultimately, investing in quality gaskets is essential for the success and sustainability of oil and gas operations.