High Pressure Fittings Connections in oil and gas industries ( buy, sale, price, export, import, from to in uae dubai )

The oil and gas industry plays a crucial role in the global economy, providing fuel for transportation, electricity generation, and various other industrial processes. One of the key components of this industry is high-pressure fittings connections, which are used to ensure the safe and efficient transfer of oil and gas across different systems.

In the oil and gas industry, high-pressure fittings connections are used to connect various components such as pipelines, valves, pumps, and pressure vessels. These fittings are designed to withstand extreme temperatures, pressures, and environmental conditions, making them essential for the reliable and efficient operation of oil and gas infrastructure.

The use of high-pressure fittings connections in the oil and gas industry is particularly important in the United Arab Emirates (UAE), especially in cities like Dubai, which are major hubs for the industry. The UAE is one of the largest exporters of oil and gas in the world and has a well-established infrastructure for the production, transportation, and distribution of these resources. As a result, the demand for high-pressure fittings connections in the UAE is high, with companies seeking reliable and durable products to support their operations.

In Dubai, there are numerous companies that specialize in the manufacture and supply of high-pressure fittings connections for the oil and gas industry. These companies offer a wide range of products, including pipe fittings, flanges, valves, and connectors, all designed to meet the specific requirements of the industry. The quality of these fittings is crucial, as any failure could result in leaks, spills, or other safety hazards that could have serious consequences for the environment and human health.

The price of high-pressure fittings connections in Dubai can vary depending on factors such as material, size, pressure rating, and design complexity. While some companies may offer lower prices, it is important for buyers to prioritize quality and reliability when selecting fittings for their systems. Investing in high-quality fittings can help prevent costly downtime, repairs, and accidents, ultimately saving companies money in the long run.

In addition to buying and selling high-pressure fittings connections in Dubai, the UAE also engages in the import and export of these products to and from other countries. This trade helps to support the global supply chain for oil and gas infrastructure, ensuring that companies around the world have access to the components they need to operate safely and efficiently.

In conclusion, high-pressure fittings connections are essential components of the oil and gas industry, supporting the safe and efficient transfer of resources across different systems. In Dubai, the UAE, companies rely on these fittings to maintain their operations and contribute to the global supply chain for oil and gas. By prioritizing quality, reliability, and safety, companies can ensure the long-term success of their operations and contribute to the sustainability of the industry as a whole.

High Pressure Fittings Types in oil and gas industries

High pressure fittings play a crucial role in the oil and gas industries as they are responsible for connecting various components of the system that operate under high pressure conditions. These fittings must be designed to withstand the extreme pressures and temperatures that are common in oil and gas operations to ensure the safety and efficiency of the overall system. In this essay, we will discuss the types of high pressure fittings commonly used in the oil and gas industries and their importance in ensuring the smooth operation of the systems.

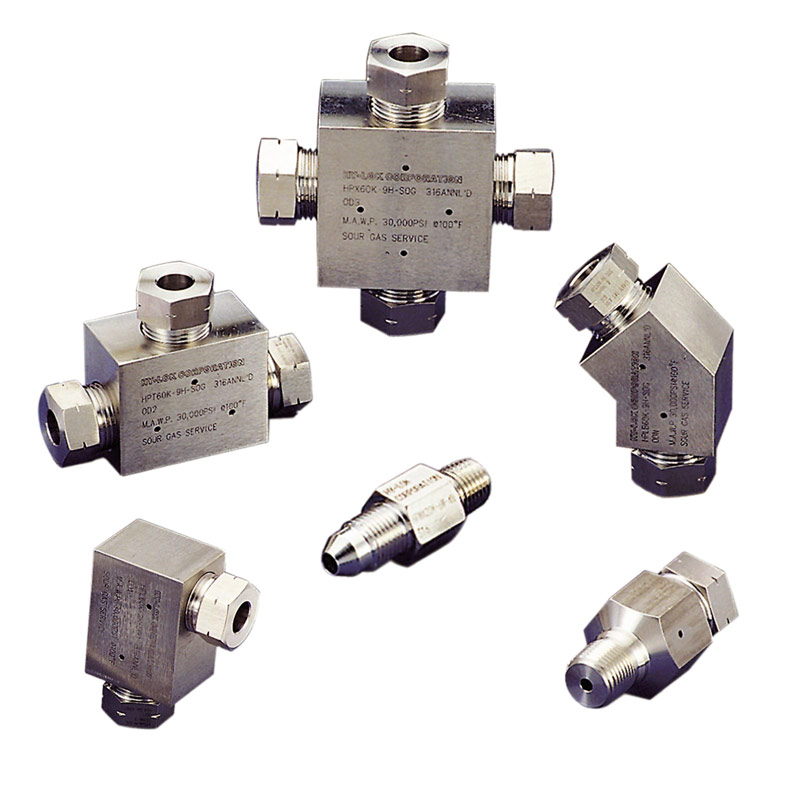

There are several types of high pressure fittings that are commonly used in the oil and gas industries, including:

1. Flanges: Flanges are used to connect pipes, valves, and other equipment in oil and gas systems. They provide a strong and leak-proof connection that can withstand high pressures. Flanges come in various types such as weld neck, slip-on, blind, and threaded flanges, each designed for specific applications.

2. Couplings: Couplings are used to connect two pipes or components together. High pressure couplings are designed to provide a secure connection that can withstand high pressures without leaking. They come in various types such as threaded, socket weld, and butt weld couplings.

3. Elbows: Elbows are used to change the direction of flow in a piping system. High pressure elbows are designed to handle the high pressure and temperature conditions in oil and gas operations while maintaining the integrity of the system.

4. Tees: Tees are used to divide the flow of liquids or gases in a piping system. High pressure tees are designed to withstand the high pressures and temperatures in oil and gas operations without leaking or rupturing.

5. Valves: Valves are used to control the flow of liquids or gases in a piping system. High pressure valves are designed to handle the high pressures and temperatures in oil and gas operations while providing reliable operation and leak-proof performance.

These high pressure fittings are crucial components of oil and gas systems as they ensure the safe and efficient operation of the equipment. Without proper fittings, the risk of leaks, ruptures, and other failures increases, posing a potential threat to personnel and the environment. Therefore, it is essential to use high-quality fittings that are designed to withstand the extreme conditions in oil and gas operations.

In conclusion, high pressure fittings are vital components of oil and gas systems that ensure the safe and efficient operation of the equipment. Various types of fittings are used in oil and gas industries, including flanges, couplings, elbows, tees, and valves, each designed for specific applications. The proper selection and maintenance of high pressure fittings are crucial to the overall safety and integrity of oil and gas systems. By using high-quality fittings that are designed to withstand extreme pressures and temperatures, companies can ensure the smooth operation of their oil and gas operations while minimizing the risk of leaks and failures.

High Pressure Fittings Brands in oil and gas industries

High pressure fittings play a crucial role in the oil and gas industry, where they are used to connect various components in pipelines and equipment that operate under high pressure conditions. These fittings are essential for ensuring the safe and efficient operation of oil and gas operations, as they help to prevent leaks and ensure the integrity of the system.

There are several brands that specialize in high pressure fittings for the oil and gas industry, each offering a range of products designed to meet the specific needs of this demanding sector. Some of the most well-known brands in this space include Parker Hannifin, Swagelok, Ham-Let, and SSP Fittings.

Parker Hannifin is a global leader in motion and control technologies, offering a wide range of high pressure fittings for the oil and gas industry. The company's fittings are known for their high quality, reliability, and durability, making them the preferred choice for many major oil and gas companies around the world. Parker Hannifin's fittings are designed to withstand extreme pressure and temperature conditions, ensuring that they can operate effectively in even the harshest environments.

Swagelok is another leading brand in the high pressure fittings market, with a reputation for producing high-quality products that are designed to meet the exacting standards of the oil and gas industry. The company's fittings are known for their precision engineering and exceptional performance, making them a popular choice for a wide range of applications in the oil and gas sector. Swagelok's fittings are also designed to be easy to install and maintain, helping to minimize downtime and reduce operating costs for oil and gas companies.

Ham-Let is a well-established brand in the high pressure fittings market, offering a comprehensive range of products that are designed to meet the specific needs of the oil and gas industry. The company's fittings are known for their robust construction and superior performance, making them a popular choice for use in critical applications where safety and reliability are paramount. Ham-Let's fittings are also designed to be leak-proof and corrosion-resistant, ensuring that they can withstand the harsh conditions often found in oil and gas operations.

SSP Fittings is another leading brand in the high pressure fittings market, with a reputation for producing high-quality products that are designed to meet the stringent requirements of the oil and gas industry. The company's fittings are known for their exceptional performance and reliability, making them a trusted choice for many major oil and gas companies. SSP Fittings' fittings are also designed to be versatile and easy to install, allowing for quick and efficient installation in a wide range of applications.

In conclusion, high pressure fittings are a critical component of the oil and gas industry, helping to ensure the safe and efficient operation of pipelines and equipment that operate under high pressure conditions. There are several brands that specialize in high pressure fittings for the oil and gas industry, each offering a range of products designed to meet the specific needs of this demanding sector. Whether it is Parker Hannifin, Swagelok, Ham-Let, or SSP Fittings, these brands are trusted by oil and gas companies around the world for their quality, reliability, and performance.