Bolt and nut in oil and gas industries ( buy, sale, price, export, import, from to in uae dubai )

Bolts and nuts are essential components in the oil and gas industry, as they are used in a wide range of applications such as pipelines, refineries, drilling rigs, and offshore platforms. These fasteners are crucial for ensuring the safety and integrity of equipment and structures in the industry, as they help to securely hold components together and prevent leaks and other potential hazards.

In the UAE, Dubai is a hub for the oil and gas industry, with a growing demand for bolts and nuts to support the booming sector. As such, there is a thriving market for buying, selling, exporting, and importing these fasteners in the region.

The price of bolts and nuts in the oil and gas industry can vary depending on factors such as size, material, and quality. High-quality fasteners made of stainless steel or other corrosion-resistant materials may be more expensive, but they offer superior performance and longevity, making them a worthwhile investment for companies in the industry.

When it comes to exporting and importing bolts and nuts in the UAE, Dubai serves as a key gateway for international trade due to its strategic location and well-established infrastructure. Companies in the region can easily source fasteners from manufacturers around the world, ensuring a steady supply of high-quality products for their operations.

In addition to local demand, Dubai also serves as a hub for re-exporting bolts and nuts to other countries in the Middle East and beyond. The city's efficient logistics and transport networks make it a convenient and cost-effective base for companies looking to distribute fasteners to markets in the region and beyond.

Overall, bolts and nuts play a crucial role in the oil and gas industry, and Dubai's position as a global trade hub makes it an ideal location for companies to buy, sell, export, and import these essential fasteners. As the industry continues to grow and evolve, the demand for high-quality bolts and nuts is likely to increase, providing ample opportunities for businesses in Dubai and beyond.

Bolt and nut Types in oil and gas industries

Bolts and nuts are essential components in the oil and gas industry, playing a crucial role in ensuring the safety and efficiency of various equipment and structures. There are several types of bolts and nuts used in the oil and gas industry, each with specific characteristics and applications that are vital for the successful operation of oil and gas facilities.

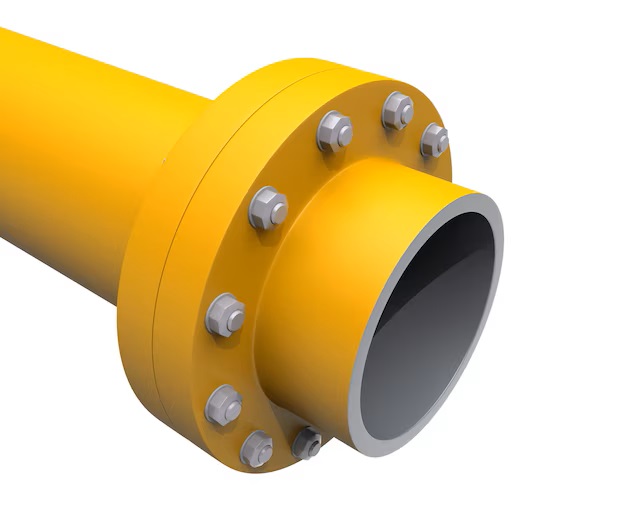

One of the most common types of bolts used in the oil and gas industry is the hex bolt, which is a six-sided bolt with a hexagonal head. Hex bolts are commonly used in applications where high strength and durability are required, such as in pipeline construction and refinery equipment. Another commonly used bolt type is the stud bolt, which is a type of bolt that has threads on both ends and is used to fasten two flanges together. Stud bolts are often used in pressure vessel and piping applications where high temperature and pressure conditions are present.

In addition to hex bolts and stud bolts, there are several other types of bolts and nuts used in the oil and gas industry, including socket head bolts, carriage bolts, and eye bolts. Each type of bolt and nut has its unique characteristics and applications, making it essential for engineers and technicians in the oil and gas industry to understand the different types of bolts and nuts available and their respective uses.

The selection of the right type of bolt and nut is critical in the oil and gas industry, as using the wrong type of fastener can lead to catastrophic failures and accidents. Factors such as material compatibility, corrosion resistance, and strength requirements must be considered when selecting bolts and nuts for oil and gas applications. Additionally, proper installation and maintenance practices are crucial to ensuring the longevity and reliability of bolts and nuts in the oil and gas industry.

In conclusion, bolts and nuts are integral components in the oil and gas industry, playing a vital role in ensuring the safe and efficient operation of equipment and structures. Understanding the different types of bolts and nuts available, their characteristics, and applications is essential for engineers and technicians working in the oil and gas industry. By selecting the right type of bolt and nut and following proper installation and maintenance practices, oil and gas facilities can operate safely and efficiently, minimizing the risk of accidents and downtime.

Bolts and nuts play a crucial role in the oil and gas industry, as they are responsible for holding together various components of equipment and pipelines. These fasteners are essential for ensuring the safe and efficient operation of facilities in this industry, as they help to prevent leaks, provide structural support, and maintain the integrity of the infrastructure.

In the oil and gas industry, bolted connections are used in a wide range of applications, from securing valves and flanges to holding together pipelines and storage tanks. These connections must be able to withstand extreme conditions, such as high temperatures, pressure, and corrosion, which are common in the oil and gas industry. Therefore, it is crucial to use high-quality bolts and nuts that are specifically designed for these demanding environments.

One of the key considerations when selecting bolts and nuts for use in the oil and gas industry is ensuring that they meet the required standards and specifications. This includes considering factors such as material composition, size, strength, and corrosion resistance. Using the wrong type of fastener can lead to catastrophic failures, resulting in leaks, spills, and potential harm to personnel and the environment.

Another important aspect of using bolts and nuts in the oil and gas industry is proper installation and maintenance. Bolts must be tightened to the correct torque specifications to ensure a secure connection, while regular inspections and maintenance are essential to identify any signs of wear or corrosion that could compromise the integrity of the fasteners. In some cases, specialized tools such as torque wrenches and tensioning equipment may be required to properly install and maintain bolts in high-pressure and high-temperature environments.

Additionally, in offshore oil and gas operations, where equipment is exposed to harsh marine environments, special coatings and materials may be used to protect bolts and nuts from corrosion. This helps to extend the lifespan of the fasteners and reduce the risk of premature failure.

Overall, bolts and nuts are critical components in the oil and gas industry, and their proper selection, installation, and maintenance are essential for ensuring the safety and efficiency of operations. By using high-quality fasteners that are specifically designed for the demanding conditions of this industry, companies can minimize the risk of equipment failures and ensure the longevity of their infrastructure.

Bolt and nut Brands in oil and gas industries

In the oil and gas industry, the use of high-quality bolts and nuts is crucial to ensuring the safety and efficiency of operations. These fasteners are used in a wide range of applications, from securing pipelines and machinery to ensuring the structural integrity of important components. As such, choosing the right brand of bolt and nut is essential for maintaining the integrity of the equipment and structures in the oil and gas industry.

There are many different brands of bolts and nuts available on the market, each with its own unique features and benefits. Some of the most popular brands in the oil and gas industry include Hexagon, Unbrako, Hilti, and B7. These brands are known for their high-quality products that are specifically designed to withstand the harsh operating conditions encountered in the oil and gas industry.

Hexagon, for example, is a well-known brand that specializes in the production of high-strength bolts and nuts. Their products are made from durable materials, such as carbon steel, stainless steel, and alloy steel, and are designed to provide maximum performance in demanding applications. Hexagon bolts and nuts are used in a wide range of oil and gas industry applications, from securing wellheads to connecting pipelines.

Unbrako is another popular brand that is known for its high-quality fasteners. Their products are manufactured to the highest standards and are designed to provide maximum reliability and durability in the most challenging environments. Unbrako bolts and nuts are commonly used in offshore drilling rigs, refineries, and petrochemical plants where safety and reliability are paramount.

Hilti is a global brand that is well-known for its innovative products and solutions. Their bolts and nuts are designed to provide maximum strength and durability, making them ideal for use in the oil and gas industry. Hilti products are used in a wide range of applications, from securing drilling equipment to anchoring platforms and structures.

B7 is another brand that is highly regarded in the oil and gas industry. Their bolts and nuts are manufactured to the highest standards and are designed to provide maximum strength and reliability in demanding applications. B7 products are commonly used in pressure vessels, pipelines, and other critical components in the oil and gas industry.

Overall, the choice of bolt and nut brand in the oil and gas industry is critical to ensuring the safety and efficiency of operations. By choosing a reputable brand that offers high-quality products, companies can minimize the risk of equipment failure and downtime, leading to increased productivity and profitability. With so many brands to choose from, companies in the oil and gas industry should carefully consider their specific needs and choose the brand that best meets their requirements.Ultimately, the use of high-quality bolts and nuts is essential for ensuring the safety and efficiency of operations in the oil and gas industry, and choosing the right brand is key to achieving this goal.